Woven from chaos

Harnessing entropy to order nanomaterials

One of the driving laws of thermodynamics is that the entropy of an isolated system cannot decrease over time—essentially, any system left to itself will eventually reach the state of maximum disorder. We fight against increases in entropy every day, like when your neatly organized room seems to sprout piles of strewn clothes on its own, or when that neatly organized line devolves into a crowd once the gates to a venue open. Chemists and materials scientists often have to fight entropy as well when synthesizing desired molecules or materials, as the process of organizing atoms and molecules into specific formations often involves decreasing entropy, which requires energy input. But what if we could harness the power of entropy to spontaneously form useful materials instead?

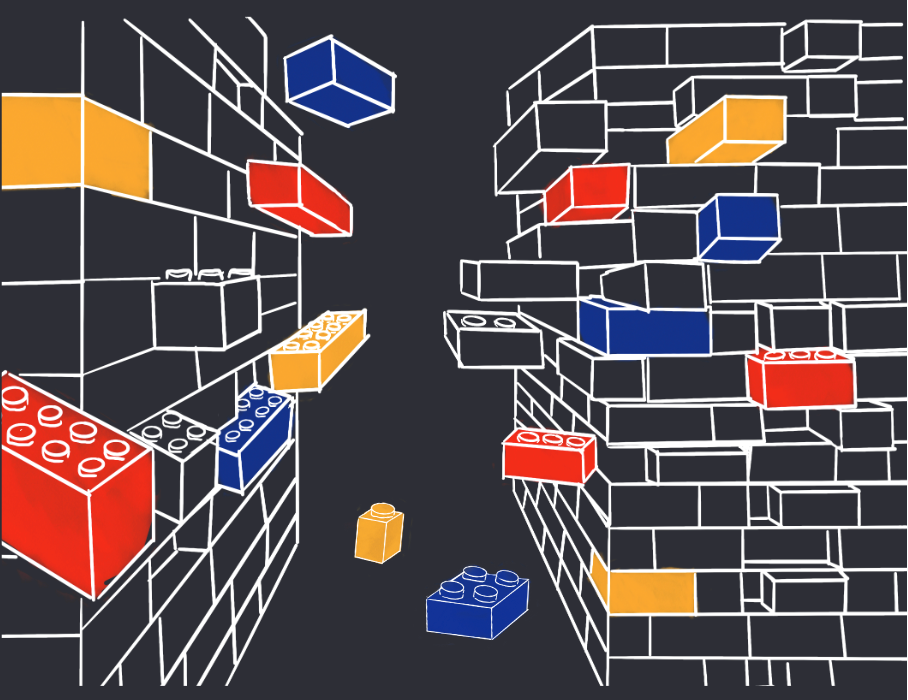

Researchers in Ting Xu’s lab have been exploring that exact idea in their pursuit of functional materials made up of nanomaterials, which require assembly on the smallest of scales. Scientists have become skilled at producing single nanosheets, like miniscule bricks, but issues arise when trying to construct larger materials out of those sheets. While a bricklayer can build a wall piece by piece, making sure there are no holes or defects, nanosheets are far too small to be built up in this way. They can be deposited layer by layer, but there is little to no control over where each sheet comes to rest relative to its neighbors, resulting in gaps in the overall surface. So how can scientists assemble nanosheets into useful materials? Xu is especially interested in addressing this problem. “This is where you can think about how you’re going to combine basic nanoscience with transformative manufacturing,” she says. “It’s much more demanding than sheer exploration. You have to be active when designing a system, manipulating it—you need to have control.”

To achieve this, Xu and her students used a mixture of block copolymers (polymers made of several different, repeating building blocks, rather than a single monomer), nanoparticles (made of ZrO2), and small molecules (3-pentadecylphenol). After years of research, they found that this exact blend has a unique property when organized together. Although assembling individual particles together usually decreases the entropy of a system, this mixture of building blocks has higher entropy when organized together. The ability of the small molecules to incorporate in numerous positions and conformations in the final structure increases its entropy compared to the individual building blocks, which interact in a more ordered manner when only amongst themselves. Because of this property, mixtures of these building blocks assemble spontaneously under the proper conditions, forming nanosheets with extremely few defects. Essentially, the wall is able to build itself brick by brick rather than laying down massive, pre-built sections next to one another. This leads to both fewer and smaller gaps, a drastic improvement over material assembly from individual nanosheets. Each component is critical, with the block copolymers giving the sheets structure, the nanoparticles imparting critical properties such as stiffness and impermeability, and the small molecules driving assembly. However, to bridge the gap between basic science and real-world application, this technique must be capable of producing usable materials.

To demonstrate the applicability of this technique, the Xu lab focused on constructing barrier coatings, which are found in products as varied as semiconductors to potato chip bags, and require unique properties depending on what substances the barriers are meant to keep out. By evaporating solutions containing mixtures of the three building blocks, they were able to construct thin films composed of over 200 parallel nanosheets with extremely low defect densities. Because these films have so few defects, they are effective at blocking the passage of water vapor, organic compounds, and electrons. Due to these qualities, they have potential as waterproof coatings, air filters, and electronics coatings. One of Xu’s major takeaways from this work is that scientists must learn to deal with nonideal conditions to find applications for their research. “In the lab, you use test tubes, you dry your glassware, you crystallize your compounds. In industry, they don’t do that—they can accommodate, and often use very complex formulations.” Despite the success of their testing, Xu doesn’t have any plans to commercialize her research just yet. “The challenge is that I love science too much,” she laments. “But, if someone wants to do a startup, we’ll be happy to support them.”

So, what’s next for the lab? Professor Xu sees this work as a potential wake-up call to the academic community about the potential of entropy to enable synthesis. “Entropy-driven composite formation, especially with this level of order, is new, and we were ecstatic to see the data,” she says. “There’s just so much we still don’t understand.” With this novel technique in hand, Xu and her researchers hope to continue to push the boundaries of not only what science can discover, but also how it can transform those discoveries into functional applications.

This article is part of the Spring 2024 issue.