As 3D printing has become a more common option for designers and builders, researchers are exploring replacing the plastic printing material they use, with natural alternatives. Using biological materials such as plant fibers and bio-derived resins helps reduce the environmental impact of 3D printing, and can also help inspire us about new ways to construct our world.

3D printing began as a commercial prototyping technology in the fast-paced consumer goods industry, enabling product designers to quickly try out designs in printed plastic, instead of waiting for the final production-ready object. Over the last few years, 3D printing has become more affordable and captured the imagination of makers and innovators, too, offering the ability to make nearly anything a creator can dream up. So far, 3D printing has relied on melting polymer filaments derived from crude oil that have heavy environmental impacts. Now, teams of researchers at UC Berkeley are exploring how to move beyond plastic and use natural materials that can help reduce their printing impact.

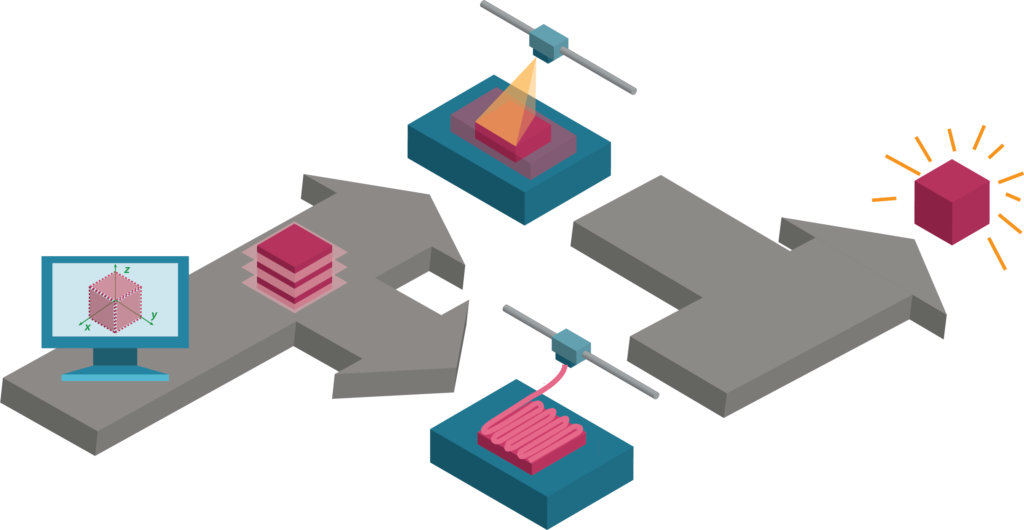

3D objects are printed layer by layer. Two common printing methods with different materials are shown here: fused filament fabrication (FFF) and stereolithography (SLA).. Credit: Jing Dai

3D objects are printed layer by layer. Two common printing methods with different materials are shown here: fused filament fabrication (FFF) and stereolithography (SLA).. Credit: Jing Dai

Fused plastic is often used for prototyping products because it can be easily formed into any shape. However, as 3D printing becomes more prevalent, and greater volumes of polymer materials are being used, there is an increasingly heavy toll on the environment in terms of energy and waste. Over 25 pounds of waste plastic filament is generated each week from the various 3D printing centers on campus, and these require a lot of crude oil, energy, and water to be processed into the filament 3D printers use. By finding ways to reuse the waste plastic, and exploring how natural materials made from plant fibers can be used instead of plastic filaments, researchers are working to help reduce 3D printing’s impact.

To lessen the environmental impacts of 3D printing, researchers at UC Berkeley are exploring ways to replace crude oil derived polymers with natural materials such as wood and bio-derived resins. They are finding that these natural materials are often lower-cost and lower energy-intensive options, due to being made from the waste of other manufacturing processes. Wood is one of the examples of a waste that can be reused for 3D printing. Manufacturers who use lumber create a constant stream of waste wood products, such as sawdust, which can be turned into useful fiber materials for 3D printing instead of being disposed of. To glue these wood fibers together, resins are used consolidate the material from a liquid printable paste into a solid material. Resins are usually made from crude oil derivatives, but bio-derived resins are also helping replace this dependence. Bio-derived resins are made from plant-based sources of carbon that are reclaimed from other wastes from industrial processes, helping save the energy and raw materials that would have been used otherwise. Until recently they have not been developed into printable materials, but now research laboratories on campus are developing new ways to use old materials.

Got wood?

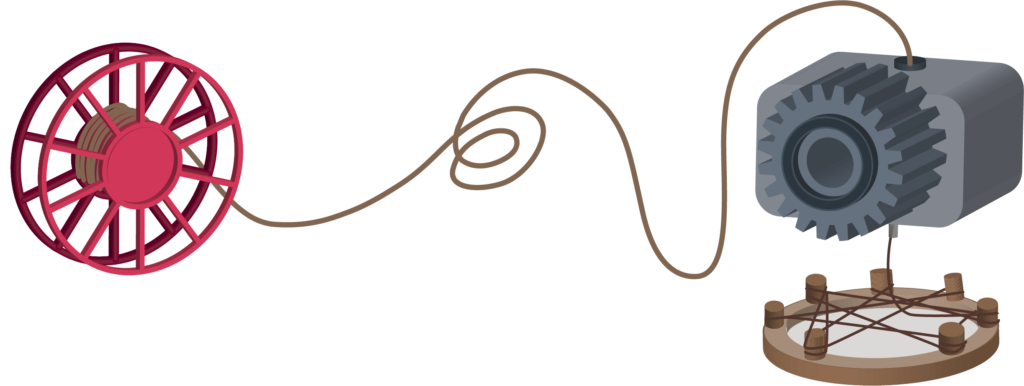

To create the bird's nest, a 3D printing head was reengineered to work as a weaving arm programmed to thread the fibers. Credit: Jing Dai.

To create the bird's nest, a 3D printing head was reengineered to work as a weaving arm programmed to thread the fibers. Credit: Jing Dai.

Because wood is strong and durable, and is also widely available as a waste product from manufacturing industries, UC researchers in the College of Environmental Design are exploring waste wood as an alternative building material in 3D printing projects. Maria Paz Gutierrez is a professor in the College of Environmental Design and the founder of BIOMS, an interdisciplinary research initiative intersecting architecture and sciences. Her research group looks to natural forms to find inspiration for more efficient and less environmentally damaging construction methods.

Under Professor Gutierrez’s guidance the architecture graduate team found inspiration from an unusual source: weaverbird nests. Weaverbirds build some of the most elaborate hanging nests of the avian world, which are unusually strong despite using minimal amounts of plant fibers. By making use of intricately woven layers, weaverbirds make structures that can support the relatively heavy weight of a family of birds, which Professor Gutierrez realized could suggest more efficient construction methods.

The 3D printed nest project grew from Professor Gutierrez’s Plant Fiber: Origins seminar. “Through 3D printed natural material filaments and 3D weaving we are redefining and reclaiming traditional crafts through digital manufacturing methods. Natural fibers have been woven into materials for centuries, but the idea here is to explore the opportunity for new construction materials using digital weaving of plant fibers” she explains.

To find out just how weaverbirds made these durable but dainty nests, Professor Gutierrez’s students explored the complex tangle of fibers using a 3D scanning machine, which measured and mapped each strand of grass. Once they could explore the nest inside and out using a digital model, the team could identify the looped fibers and netted patterns of twigs that give the nest its superior strength and insulation. Specifically, they found that weaverbirds weave a combination of flexible fibers with longer, stronger fibers that allow the structure to flex and absorb any impacts. By following this alternating weave pattern, the team has learned to replicate the nest structure and can now scale up for a human-sized nest to find out how these natural building methods may work in our urban world.

To assemble a human-sized weaverbird nest, Professor Gutierrez’s team re-engineered an existing 3D printer to print a paste of pulped wood waste and hemp fibers. Robotic arms then combine the paste with wood fibers to intricately weave a strong but light nest. The stronger, stiffer bamboo fibers bear the weight of the nest, while smaller more bendable fibers keep the nest pliant and resilient. Combined together, these form a strong and flexible structure, which was exhibited in the UC Botanical Gardens atrium last summer. Professor Gutierrez explains that building a nest is more than just assembling plant fibers in the right order—the team worked for over a year to find out how natural construction techniques can be merged with digital technologies to find new, less energy intensive ways to build. “We have an enormous amount of natural materials waste, like coconut husks, bamboo and wood. Twenty million tons per year of coconut husks alone are a byproduct of agricultural production in the world. 3D printing of natural fibers allows for on-site fabrication and on-site reclamation. We can use local natural waste, and provide the opportunity of incorporating traditional crafts—it’s an economic and cultural opportunity.” With Professor Gutierrez and her team working to find ways to use these less environmentally impactful natural materials with printing techniques, reusing waste could become more widely adopted to help us reduce our reliance on plastic.

Printing into the 3rd dimension

Researchers are also finding new technologies that can not only help us reduce the environmental toll of 3D printing with traditional plastics, but also have a net positive impact on the environment. Concrete is one of the most widely used construction materials in the United States, but it has a heavy environmental impact. Concrete structures need to be supported by a wooden framework while it hardens and cures, resulting in a lot of wasted energy and time. Ideally, the need for these support structures could be eliminated by 3D printing concrete.

Professor Ronald Rael, who holds the Eva Li Memorial Chair in Architecture at UC Berkeley, took on the challenge of finding innovative ways of printing entire buildings with biological-based resins. Partnering with Entropy Resins, who are working to replace petro-chemicals with renewable, bio-based materials, Professor Rael helped develop a new concrete that was 3D printable and that cured itself without the need for any supports. “Sixty percent of the cost of construction is the wooden supports, and 3D printing means not relying on formwork, saving money” explains Rael.

To demonstrate that 3D printing can make concrete buildings without needing wasteful wooden supports, Professor Rael and his team of graduate students created one of the largest 3D printed cement sculptures in the US. Bloom, a bio-inspired 9 foot tall tower, was made using 840 individually 3D printed blocks and constructed in the courtyard of the College of Environmental Design. The tower’s construction was inspired by nature, using square-shaped honeycomb blocks designed to be assembled together to make the tower self-supporting, with each brick holding up its neighbor.

The goal of the tower is to show how less environmentally impactful natural materials, such as bio-derived resins, can still meet the needs of structurally demanding buildings. Professor Rael explained the motivation to build the tower was driven by the need to show that natural materials can be used to make cost-efficient, environmentally-friendly structures. “The way this began was realizing [current methods of] printing were way too expensive. The question was, if we need to reduce the cost, what can we get for free?” By finding and adding a bio-based binding resin that is processed in a way that reduces its greenhouse gas emissions by up to 50 percent compared to crude oil based resins, Professor Rael was able to print cement that had less of an environmental impact.

Rael explains the art installation also serves as a way to show that the previous limitations of using 3D printing to create architectural structures—namely finding cement that can be printed out as a liquid paste but still set as a cohesive solid—can be solved by the precise printing of blocks and looking to bio-based materials for the solution.

To make a printable cement possible, the team needed to find a way to use the cement formula that could freely flow through the printer nozzle but also properly cure in time to form the shape needed, and the solution was the eco-resins that bind the cement structures firmly together. “We add a very small amount of water, powder, and aggregate, and introduce a bio-polymer for added strength” explains Rael. “The cement formula allows it to be very lightweight. The more lightweight, the less carbon dioxide emissions, the less energy used.”

In addition to specific materials that reduce the production of greenhouse gases, the method of printing itself helps reduce the carbon footprint of these cement structures. The ability to print each individual brick in the exact shape and location required for the final product keeps the energy and material supplies to a minimum as Rael advocates “If you build light, you lessen the impact on the environment.”

While we are not yet able to print out entire buildings, Rael’s tower helps prove we can create structures using 3D printing and natural materials as alternatives to traditional concrete pouring, eliminating the need for wasteful wooden supports. By finding ways to switch to less environmentally damaging materials, and new ways to print them out, our concrete jungle could slowly become greener.

Print it yourself

Top left: The 20-pound bird's nest was composed of 400 3D printed pieces using wood and hemp fibers.

Top left: The 20-pound bird's nest was composed of 400 3D printed pieces using wood and hemp fibers.

UC Berkeley is also working to make 3D printing available to everyone to campus, establishing several 3D printing studios open to anyone who would like to make their ideas into an object. There are now five different hubs for design innovation using 3D printing, equipped with the latest 3D printing machines, access to computer aided modelling design software, and resident 3D printing specialists to assist. Recently the UC Berkeley Center for Information Technology Research in the Interest of Society (CITRIS) Invention Lab became the first University in the country to launch a 3D printer lending library, loaning portable 3D printing machines directly to students. The CITRIS GOFAB Lab lends small, transportable 3D printing units free of charge, so creators can take a printer home. Designers can also get their ideas printed out even if they are new to 3D printing, at 3D printing studios designed to be accessible to students such as the b.makerspace in the Moffitt Library, which has professional technicians available to train users in how to create models and turn them into real printed objects.

As UC Berkeley’s research groups continue to find new ways of using 3D printing and the number of Makerspaces to print out objects on campus grows, more efforts are being made to make sure the current polymer materials make the lowest impact they can. While 3D printing designers explore the range of what they can print for research and for fun, plenty of failed prints and leftover pieces of plastic are produced. To stop these rejects from making their way to the local landfill, UC Berkeley’s students are aiming to help the University become a zero waste operation through the 3D Printer Filament Reclamation Project. The campus’s 3D printing community has partnered with the Green Initiative Fund to collect and reuse any excess and waste material for other 3D printed projects. Spearheaded by students, the project will collect the waste 3D printed filaments, and then process them using grinding machines to turn them into upcycled 3D printing filaments. Removing and reusing the waste plastic also stops it from eventually contaminating natural water streams, as plastics break down into microscopic sized particles that then pollute our water resources. By diverting these materials into reuse, the team also hopes to make recycled filaments that are free for all educational departments, helping make 3D printing accessible for everyone.

The increasingly pressing need to find materials that can be used with the new generation of 3D printing fabrication technologies, without being derived from crude oil, has pushed scientists to try to adapt natural materials. Building structures that are inspired by nature, whether it’s a 9 foot concrete tower made from bio-resins, or a human-sized woven nest, helps us find more efficient ways to use resources that would otherwise go to waste. With researchers on campus working to find novel ways to use less impactful materials derived from industrial by-products, and new ways to build without needing wasteful supports, printing out buildings seems closer than ever. By redirecting plant fibers destined for disposal into making a new material, and using bio-derived resins to make them into strong materials, we can start to reduce our reliance on crude oil. Nature has already provided us with a range of resources that can solve complex material needs, such as being strong but flexible, and durable but not environmentally harmful. By combining these less impactful materials with the latest ways of building by using 3D printers, the future could well be printed by nature.

There are many on-campus 3D printing facilities available for students. Come check out yourself!

There are many on-campus 3D printing facilities available for students. Come check out yourself!

Sonia Travaglini is a graduate student in mechanical engineering.

Design credit: Jing Dai

This article is part of the Spring 2018 issue.