The tags on our clothes, the soles of our shoes, even the backs of our phones may one day read: “Made by Biology.” Over millennia cells have evolved to construct materials as diverse as wood, glass, and even glue. Rather than use toxic chemicals and high pressure or heat, this architectural power comes from instructions encoded in DNA and carried out by protein chemistry.

Understanding nature’s material design principles has inspired the new field of biofabrication. Some of the most well studied biofabricated materials include spider silk, animal leather, oyster nacre, diatom glass shells, organoids, and bone.

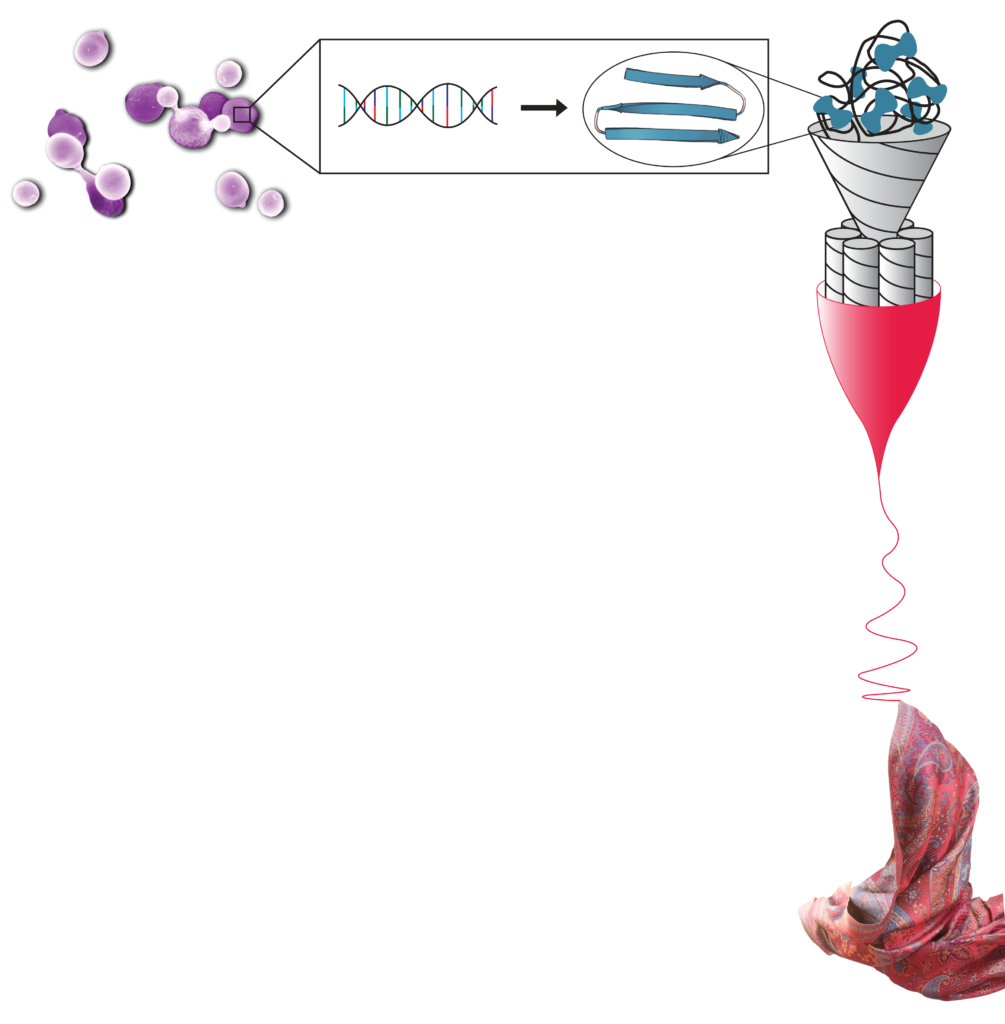

Biofabricated materials are built from simple biological components. These molecular building blocks can be as small as a few atoms and as large as a complex protein. Cells provide specialized chemical environments that help to assemble the blocks into larger and larger structures. As they assemble, the building blocks gain identifiable shape and form, like constructing a house from stacks of wood.

Scientists seeking to understand and recapitulate biofabrication methods must first understand the molecular building blocks involved. The lab of Phillip Messersmith, UC Berkeley Professor of Material Science & Engineering and Bioengineering, studies marine adhesive proteins. These powerfully reactive molecules form the basis of waterproof glue. Mussels and barnacles produce these glue proteins to help them stick to tidepool rocks or the hulls of ships.

Prior to Messersmith’s work, earlier research focused primarily on how mussels and barnacles make glue proteins. In contrast, Messersmith’s lab took an engineering approach, designing adhesive synthetic polymers inspired by the native glue proteins. “It’s not necessary to fully understand a biological system in order to begin to ... mimic it,” says Messersmith, adding that waiting to fully understand a biological material may diminish the chance it is used in real-life applications.

While Messersmith uses synthetic polymers, other researchers seek to make materials using natural proteins. However, studying biofabricated materials in their native organism can be difficult. One new approach is to use microbes to produce these protein building blocks. Biofabricated materials are, by nature, biological—meaning that the instructions to make the building blocks are encoded in genetic material. This allows researchers to use an organism like yeast that is cheap and easy to grow, instead of harvesting proteins from more complex and slower-growing native organisms, like mussels.

With the molecular building blocks in hand, the final step of the biofabrication process is to assemble them into a higher order structure. Like how sawing and hammering help assemble a house, these processes are specialized chemical bonds or physical manipulations that form the molecular building blocks into larger structures, such as changing acidity, extruding the material, or drying.

These new methods to design and make materials notably attracted the attention of non-scientists, especially artists and designers. They introduced new questions and approaches to the field, asking not how biology designs itself, but how humans can design with biology. They pioneered new methods to work with existing biofabricated systems, such as dying and drying biofilms to make clothes or baking mushroom roots to make sturdy bricks.

Work by these artists and engineers redefined “to biofabricate” to mean “to design with biology.” It revolutionized the development cycle to include dialogue between scientists, engineers, and designers. Designers propose new biologically inspired material designs and properties, like waterproof leather or flexible glass. Scientists follow by engineering organisms to fit those designs, and by proposing new ideas of their own. The feedback loop is inventive and continuous, driven by cross-disciplinary curiosity.

While this field is young, the potential is enormous—a fact that is not lost on most biofabrication researchers. Researchers and artists envision a future world where buildings and products are grown biologically, displacing toxic resources. Much basic research on how organisms biofabricate materials remains to be done. How do organisms produce glass without high heat and pressure? Can we one day grow bones in the lab? With scientists, engineers, artists, and designers coming together to tackle these broad questions, a biofabricated future is fast approaching.

Silk is a well studied biofabricated material. DNA in cells encodes silk proteins, which fold up and bond together to make nanofibrils (gray). These nanofibrils bundle into larger fibers (red) that are then woven into silk products. Design credit: Alexandra Ramsey

Silk is a well studied biofabricated material. DNA in cells encodes silk proteins, which fold up and bond together to make nanofibrils (gray). These nanofibrils bundle into larger fibers (red) that are then woven into silk products. Design credit: Alexandra Ramsey

Julia Borden is a graduate student in molecular and cell biology.

Design credit: Alexandra Ramsey

This article is part of the Spring 2018 issue.