You probably eat mushrooms, but you likely don’t know that fungi have many other applications, including being used to make compostable mushroom bricks, packaging, and all sorts of materials. Once merely a tasty morsel, fungi now support a fast-paced biotech industry, with scientists and entrepreneurs developing new applications that could make them a more integral aspect of our lives.

Neither plants nor animals, fungi make up their very own kingdom. They form the underground fabric of our world, with giant hidden networks involved in many aspects of our food and ecosystems. They are the recyclers of our planet, digesting carbon-based organic matter to make new living matter and nutrients. As more studies are done, we add more to the list of things fungi can do, with research providing the information and technologies needed to use fungi for all sorts of products. From mushroom bricks to clothing, fungi offer a huge range of unusual and novel applications. Entrepreneurs have identified fungal species that can grow into hard and tough blocks, forming bricks that can be used for constructing houses. Recently, a method has been developed to manufacture a replacement for animal-based leather using the flesh of a fungal species.

The author with a mushroom and mycology composite. Credit: Dan Lurie

The author with a mushroom and mycology composite. Credit: Dan Lurie

As a doctoral researcher in the UC Berkeley Department of Mechanical Engineering studying with Professor Hari Dharan and Professor Alice Agogino, I became interested in fungi by looking to nature for ideas of how to engineer alternatives to synthetic materials. I’ve become captivated by them, trying to understand how simple mushrooms can be used to create such strong materials. The promise of using fungi to produce useful resources inspired me to learn more about the biology, properties, and applications of fungi, both at UC Berkeley and with startups around the Bay Area. As an engineer it’s exciting to explore novel materials that have never been tested, and this drew me into an entirely new field of research and a whole world of fungi.

Waste not, want not

We all know the cute, round button mushroom Agaricus bisporus in our British fry-ups and the delicate, slender enoki mushroom Flammulina velutipes in our Vietnamese pho—but there are millions of fungi species.

Professor Tom Bruns of the Department of Plant and Microbial Biology at UC Berkeley studies the ecology and evolution of fungi. He is working to understand how plants depend on and live with fungi all across California. Bruns explores the symbiotic associations of fungi with plant roots, called mycorrhizae. His work helps scientists understand which fungal species should be selected for development of products based on how they grow, what they like to eat, and how they will interact with other species.

Bruns, whose favorite mushroom to eat is Boletus edulis (the porcini mushroom), knows just how important mushrooms are. Sitting in an office surrounded by various samples collected from the underground world of fungi, he remarks that up to a fifth of all known species on Earth are fungi, although the exact number is hotly debated. While explaining just how important fungi are, he notes that “without them, all our ecosystems would collapse.” Fungi recycle carbon on our planet and enable plants to access nutrients in exchange for being fed themselves, creating a relationship without which neither partner can survive. “Plants need fungi to find food at the root level. [Fungi] concentrate rare minerals by finding and concentrating elements like copper, potassium, and nitrogen in exchange for sugary food from the plant,” explains Bruns. He also points out that our own food chains rely upon fungi. Our favorite drinks rely on them, too; without yeast we cannot brew beer.

The ability of fungi to digest organic substances is also being harnessed to clean up the environment. This type of environmental problem solving, called bioremediation, uses mushrooms to remove dangerous substances by mixing the toxic waste with digestible matter and fungi. The fungi then grow a threadlike mycelium, a conglomeration of thin filaments called hyphae, which secrete enzymes that digest the toxic matter. Bioremediation is “remarkable,” says Bruns. “In the crude oil spill in the San Francisco Bay, horsehair mats were used to soak up the oil and then got digested by fungi.” Once the oil is soaked up, the mats are removed and composted, allowing naturally occurring species of fungi to digest the horsehair and toxic oil, breaking down the carbon-based pollutants and then converting the resulting material into mycelium as the fungi grow. Over time, as the compost ages and microbes break down all the organic matter into soil, the mycelium is recycled into an enriched soil which can then be used to grow plants.

Similarly, fungi can be used in bioremediation to contain and process biowaste. They can digest their way through acres of contaminated land, forming byproducts that can be used as fertilizer. This means that fungi help return nutrients to the soil without the need for artificial fertilizers, many of which can lead to serious environmental problems if overused. This natural approach to creating materials and processes that complement the environment makes fungi an interesting source from which to develop new applications and materials.

Just how strong are your "shrooms?"

Fungi have the potential to be more than just a food source. Developing new uses of fungi to produce useful materials requires a special engineering approach. This led to a discovery of how you can make materials from mushrooms. Professor Hari Dharan of the Department of Mechanical Engineering at UC Berkeley specializes in biomimicry, researching new technologies inspired by nature. Dharan and I have investigated just how strong a mushroom material can be. Using giant crushing machines that can squeeze with a force of 50,000 pounds, novel mushroom materials are poked, squished and squashed to discover their limits of strength and crushability, which scientists had never explored until now. We found that these materials are surprisingly strong.

The mushroom-based materials could be as strong as wood, behave like high-tech synthetic composites, and could also be made into composite blocks, effectively making mushroom bricks. Current synthetic composites are made of crude oil-based polymers and man-made fibers like glass fiber, and while widely used in lots of building materials, they aren’t great for the environment and generally can’t be recycled. Materials made from mushrooms mimic the way synthetic composites are structured, with the fungi reinforcing themselves, which helps give them surprising strength. “Nature can provide ideas for engineered materials. You have to ask: how would nature do that?” asks Dharan about the challenge of using the soft, organic matter of fungi to make durable products like furniture.

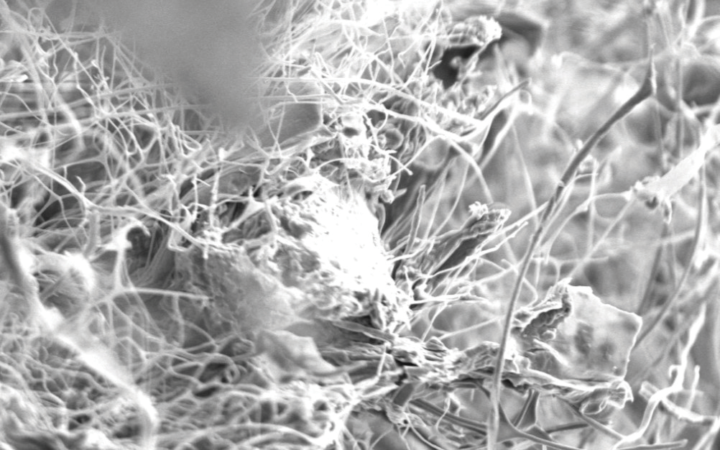

Understanding the strength of biological materials requires understanding their underlying microstructure, so we examined them used a scanning electron microscope from UC Berkeley’s Department of Earth and Planetary Sciences to find out exactly why they are so strong.

Scanning electron microscope of mycelium. Credit: Sonia Travaglini

Scanning electron microscope of mycelium. Credit: Sonia Travaglini

On the microscale, mycology materials are made from mycelium, which mushrooms use just like a tree uses roots: to seek food, to grow, and to form giant underground networks. Peering at a filament one-eighth the width of a human hair, the crisscrossing nature of the thread-like hyphae can be seen growing around chunks of wood and digesting them, forming the mycelium-based material. The individual hyphae are tiny, but as small as they are, they give the material its strength when they work together as a network.

Materials derived from living organisms often have built-in advantages over synthetic materials, such as being nontoxic and compostable. Mushroom materials exhibit these properties along with being unusually strong for naturally-grown substances due to being made up of a repeating network of tiny structures—in this case, tiny block-like cells. Compared to traditional materials, they can better resist physical damage from spreading across these cells and through the material, which can be useful in materials for construction. The mycelium contains reinforcing chitin, an organic substance found in hard-shelled animals like crabs and other crustaceans and the iridescent, rainbow-hued shells of beetles. Chitin can take many forms and can be a strong and adaptable material. This allows mycology materials to be strong despite being lightweight. Chitin makes the reinforcing beams for this cellular material and enables fungi to create a huge network of hyphae. This means that fungal networks can grow very large by making lots of smaller structures, which support them like a honeycomb.

Your room is mushroom

Developing new materials is one of the fastest growing areas for innovation, and the Bay Area is becoming a hotbed of invention for bio-based products. If you want to use mushrooms in more ways than just pleasing your palette, the most recent development of fungi is founded in the lightning-fast paced world of biotech startups. The Bay Area-based MycoWorks, a Silicon Valley design and materials engineering company, uses fungi and biotechnology to solve the need for more sustainable and less energy-intensive materials that can be grown naturally. What began with an artisan project by collaborator and entrepreneur Philip Ross has grown into a quest to use biotech to grow fungi into all sorts of products. Some of their endeavors include the production of insulating panels, cushiony foams, and even fabrics, all made of mushrooms.

As the materials that the companies grow are made of natural matter, they can be composted, degrading naturally within a few weeks. These mycology materials can even be re-digested by more fungi and re-grown into another product or material—effectively creating an infinite material loop. One can almost imagine a future zero-waste community taking waste packaging materials and effortlessly growing a new garment, like a pair of gloves.

MycoWorks is developing apparel made of mushrooms as a replacement for leather. At the recent startup accelerator IndieBio’s event, where budding biotech companies introduce their latest work, co-founder Philip Ross explained that animal-based materials require many more resources and generate polluting byproducts. Raising animals requires intensive use of water, land and crops for feed, and the chemicals used to process animal hides into leather, such as formaldehyde, are very toxic. Showing a vivid blue purse made of a new fungi-based leather, Ross extolled the benefits of creating materials in laboratories free from the constraints of intensive farming: “This new material is amazing! It feels just like leather and can be colored and embossed, and we don’t have to use toxic chemicals to tan it. It’s a whole new way forward.”

Because these new “mycoleathers” can be grown to huge sizes—they can already be cultivated to be even bigger than a whole animal skin hide—using them instead of animal leather means less wasted material and fewer wasted resources. As Ross noted, only around one third of an animal hide is finally used for leather. This is a step in finding ways to reduce the impact of fashion on the environment. While these mushroom materials are at a nascent stage of commercialization, their potential is still unfolding and scientists and engineers are working hard to make these ideas into reality.

Ganoderma lucidum and mycology composite with laminated bamboo. Credit: Dan Lurie

Ganoderma lucidum and mycology composite with laminated bamboo. Credit: Dan Lurie

Currently, there are only a handful of products on the market made from fungi. Because they’re made in small production runs, they struggle to compete with the low cost of synthetic materials already on offer. The nature of biological materials also means they vary in appearance and uniformity, which is a real challenge when scaling up production to churn out large volumes of material. Developers have to work around these complexities to make sure products turn out consistently. Another challenge in the wider use of natural materials is that using fungi for anything other than food is so novel that many people have never imagined the possibilities and are unsure about exactly what they are. As mushroom-based materials gain momentum, there is demand for more discussion and information about the advantages they offer, and scientists and engineers are continuing their work to overcome the challenges and help fungi fulfill their full potential.

Ita Li, who recently worked with OtherLabs, a San Francisco incubator which develops new technologies, is an avid supporter of the new fungi-based materials—“it’s essential,” he says. “Biotechnologies that are coming up are a new way to fulfill functions we need, just like the industrial revolution. But in this bio-revolution, you grow things which add to the planet, rather than taking away from it.” Li’s perspective shows how industry is starting to see sustainability and environmental impact as one of the most important aspects of new technologies. “I really like these materials as they clean the environment as you grow them,” he says. Most materials require very complex processing, and synthetic materials commonly need even more, often needing several raw material feedstocks that themselves require dangerous ingredients.

With mycology materials, none of this is necessary. One of the important characteristics of these materials is that they grow from waste. They eat their way through unwanted byproducts from the agricultural industry, nibbling away at sawdust, breaking it down and binding it into their own bodies. Unlike synthetic materials, this means the feedstocks used to grow mycology materials are low-cost, and the whole process of growing mycology materials captures carbon and reduces the materials' footprint. It also means materials made from fungi could be used to tackle the huge volumes of waste we produce as a society, which, despite strenuous recycling and reuse efforts, continues to partly end up in the landfill.

The future is fun-gible

Fungi remain one of the most essential parts of our ecosystem, despite being mostly hidden from view underground. Now fungi are finally getting attention from the biotech world as possible solutions to our waste problems and our ever-increasing need for materials. We have found a way to make something useful from waste without being costly, harmful, or excessively complex. Industrialized farming of plants and animals is hardly a new idea, but the world of fungi is getting attention as a readily usable source of material and a cheap and natural solution to processing our waste. So what’s next in our uses for fungi? They already form the fabric of our ecosystems, feed us, slake our thirst with beery beverages, and now they are being developed in materials to build our homes.

Fungi have become popular not just for their taste, but for what they can become. Soon, each of us may be unwrapping our latest gadgets, composting the packaging, and then enjoying a tasty lunch of mushrooms inside our mushroom brick houses. The future may well be mushroom-shaped. And that is a good thing.

Feature image credit: Christine Liu

This article is part of the Fall 2016 issue.